.jpg) |

Conductive paste, in Our country has a long history of use, but also has the most controversy. Whether the conductive paste can reduce the contact resistance of the switch and extend the service life of the switch is discussed in this paper. By definition, the commonly used conductive paste on the market, its basic performance is the same, is based on mineral oil, synthetic liposuction oil, silicone oil as the base oil, added conductive, anti-oxygen, anti-corrosion, arc suppression and other special additives, by grinding, dispersion, modified refined soft paste, play a significant effect of anti-corrosion, energy-saving effect. |

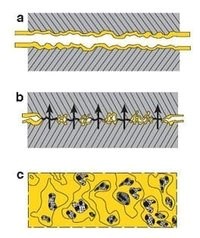

Figure 1: a switch on, b switch closed, c open and off and time-top view

In many cases, a layer of metal oxides or plastic decomposing materials is often formed on the contact surface, increasing the contact resistance. This oxide layer is usually destroyed when the contact pressure is large enough or heat is enough to form. However, the heat generated can exacerbate micro-seismic corrosion, leading to a further increase in the contact resistance. In addition to the oxidation layer, the actual effective contact area left behind becomes a-spot (Figure 1c).

At the same time, in the continuous opening and closing of the switch process, due to friction and wear, in the absence of lubricants, the actual effective contact area will continue to decrease, directly reflected in the switch's contact resistance is rising, the final impact on the actual use of the switch.

3. Can conductive paste really reduce contact resistance?

As can be seen from Figure 1c, the actual effective contact area is formed by the plastic deformation of the protruding part of the switch surface, and the contact grease is usually filled in a concave place to form an inert environment on the switch surface to avoid oxidative corrosion. In the process of switching and closing, due to the reflux characteristics of the grease, an effective oil film is formed on the contact surface to avoid wear.

For conductive paste, because of the existence of some of its conductive particles, in the concave part, may form a certain conductive channel, because the contact resistance of the conductive paste is still much larger than the metal, so the conductive paste conductive efficiency is greatly reduced, but also will bring the problem of heat. At the same time, due to the presence of conductive particles, the insulation performance of the switch and anti-arc performance, will bring further impact.

Therefore, the comprehensive assessment, conductive paste will have some improvement on contact resistance, but at the same time will have a heating, as well as insulation performance aspects of the impact, is not particularly suitable for long-term use on the contact.

4. How to choose the right contact lubricant?

The choice of contact lubricants depends mainly on the media environment in which they are located, and for Crubourd, we have the following products for you to choose from.

The lubrication products for air media environments are: