Klüber presents Klüber Summit, a specialized long-life product line designed to simplify maintenance, boost stability, and reduce operational costs for air compressors.

Rotary screw air compressors often face challenging operating conditions, including extreme heat (as high as 120°C). This harsh environment leads to the formation of varnish deposits and carbon residues within critical components, such as the compressor unit and cooling systems. Consequently, operational issues arise, ranging from sudden shutdowns due to overheating to premature lubricant degradation, frequent oil filter separator replacements, and, in severe cases, compressor unit damage. These challenges result in increased maintenance and operational expenses. Hence, the importance of scheduled maintenance and selecting top-quality lubricants cannot be overstated, as they directly determine long-term stability and cost-effectiveness.

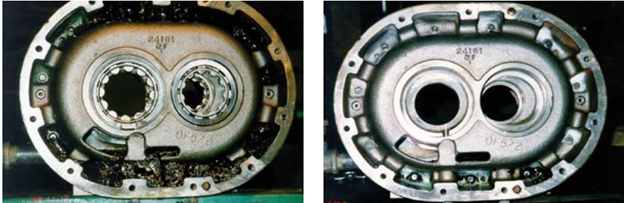

Varnish Deposits Formation in Air Compressors using low-quality oil

Varnish Deposits Formation in Air Compressors using low-quality oil While regular maintenance tasks like oil and filter replacement as well as oil separation can be efficiently handled by on-site technical teams, the more complex task of disassembling the compressor for extensive cleaning typically necessitates external service providers. This translates to extended downtime, a lack of control over maintenance scheduling, and escalated costs.

In line with the goal of streamlining maintenance, enhancing stability, and achieving cost savings in air compressor operation, Klüber Lubrication offers the

Klüber Summit product line, known for its extended life-time:

Klüber Summit Varnasolv: A concentrated solvent designed for cleaning air compressors, gearboxes, hydraulic systems, and circulating oil systems with several advantages:

- Dissolves varnish deposits and carbon residues, hence reducing maintenance costs, and enabling cleaning without the need for disassembly.

- Can be used during operation and carried out by on-site technical teams, eliminating the necessity for shutdowns.

- Easy-to-use due to its seal compatibility when added to compressor oil at a 1:10 ratio

- Efficiently cleans and prolongs the service life, resulting in minimized operation costs

Compressor Unit before and after applying Klüber Summit Varnasolv

Compressor Unit before and after applying Klüber Summit Varnasolv Klüber Summit SH 32, 46, 68 Air Compressor Oil: This synthetic air compressor oil extends oil change intervals of up to 10,000 operating hours. Its benefits encompass:

- Low maintenance and operating costs.

- Compatibility with various sealing materials, streamlining oil changes.

- Minimal vaporization behaviors

- Extended lifespans for oil filters, carbon filters, and oil separators.

- Reduced formation of oxidative sludge within the system, leading to cost savings by prolonging the life of oil filters and separators.

- Compatible with air compressors from renowned brands such as Atlas Copco, Kaeser, Boge, Hitachi, Kobelco, and Fusheng.

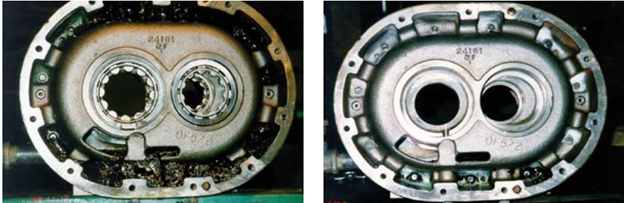

Atlas Copco GA200 Compressor Unit after 4 years of using Klüber Summit SH 46

Atlas Copco GA200 Compressor Unit after 4 years of using Klüber Summit SH 46

As a trusted technical distributor of authentic Klüber Lubrication products in Vietnam for 25 years, our company has conducted in-depth surveys and provided expert guidance. By combining Klüber Summit Varnasolv and Klüber Summit SH 46 oil, we have successfully achieved notable results in cleaning and operating rotary screw air compressors. These achievements include a 10°C temperature reduction compared to previous oils, continuous and stable air compressor operation, and significant cost savings on maintenance and operation. These successes have been demonstrated across various industries, including Cement, MDF, and Food Processing.

For more detailed on product information and specific application guidance, please reach out to our company through the provided hotline numbers. Our team of service engineers and experts is ready to provide swift assistance and address your inquiries