Polyurea grease is widely accepted as the best option for long-life applications like electric motor bearings. As a result, most businesses – even food processing and packaging plants – use standard polyurea grease in all their electric motors to avoid a drop-off in performance.

With no real food grade polyurea grease options, most food plants have been forced to risk the potential cross-contamination of non-food grade lubricants into their food-safe processes. But that’s a risk they no longer need to take.

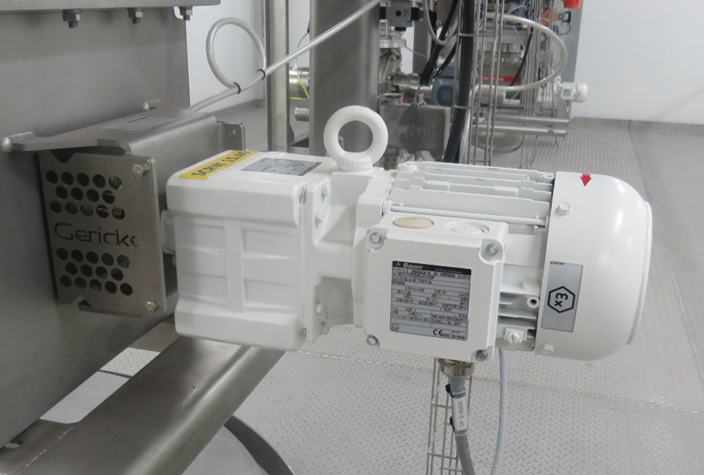

Klüberfood NH1 72-132 is a full synthetic polyurea thickened grease specifically designed for the long-term lubrication of ball and roller bearings submitted to high speeds in electric motors, ventilators, fans, centrifuges, decanters, and other machines in food processing and pharmaceutical industries. It is registered as NSF H1 and is produced and packaged in our NSF ISO 21469 certified facility.

There is no reduction in performance. We ran side-by-side comparisons with the typical polyurea motor bearing greases currently on the market, and Klüberfood NH1 72-132 fared as well or better on all the major performance metrics.

Klüberfood NH1 72-132 has been tested and found to be fully compatible with typical polyurea thickened grease, so it can be applied on top of your current polyurea grease.

It is extremely robust and versatile in diverse applications and offers the following benefits:

- NSF H1 registered

- outstanding protection from corrosion and wear

- operational lifetime as good as or better than standard industrial electric motor greases

- wide service temperature range of -30ºC to 180ºC

- high shear stability

These benefits and more make Klüberfood NH1 72-132 the ideal lubricating grease for electric motor bearings. Having your motors rebuilt? Contact your motor rebuild service and request they use Klüberfood NH1 72-132 to avoid possible cross-contamination and get one step closer to having only food-safe lubricants in your plant.

Reach out to your Vu Minh sales representative for more information.