Lubricants to meet textile industry sustainability goals

With complex production processes and many different types of machines manufacturers need lubricants which ensure continual production and at the same time help keep logistics costs as low as possible. And this is exactly what Kluber Lubrication offer you.

Kluber synthetic special lubricants offer many advantages over standard products based on mineral oil. The benefits for you include: longer service intervals, reduced downtime, higher production reliability. Moreover, the risk of contact between the yarn or fabric and the lubricants drops.

We see lubricants as a fundamental design element of textile machines. They have to match the individual component requirements to ensure optimal performance is achieved as efficiently as possible. With our speciality lubricants we can cover the entire production process in the textile industry, including:

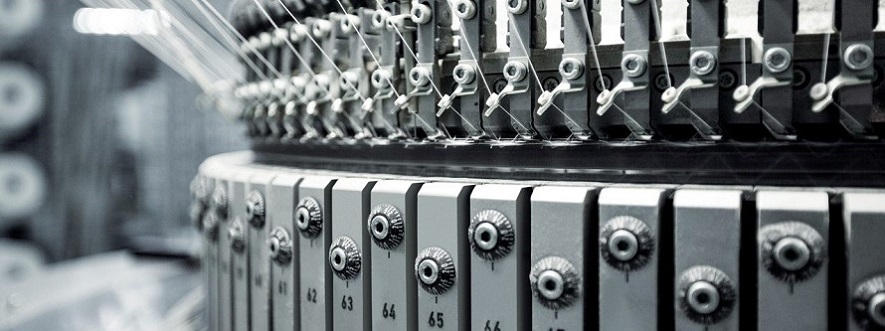

- Spinning machines: excellent corrosion protection for bearings, spinning turbines, opening rollers, spinning pumps, and spinnerets

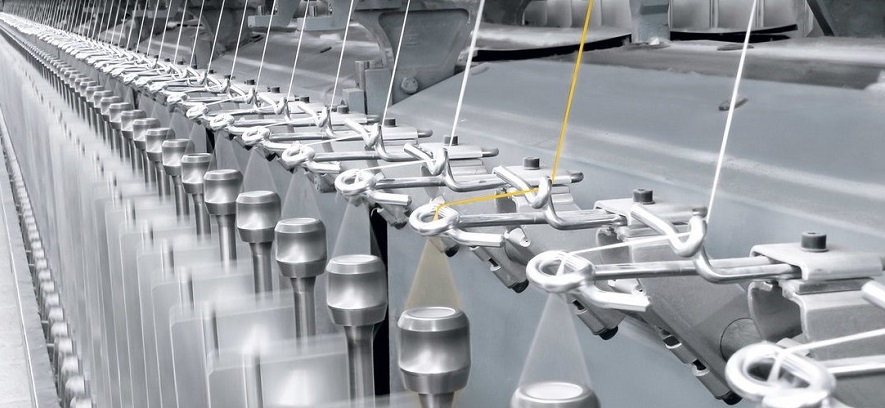

- Knitting machines: long service life with minimum maintenance requirements for needles and sinkers, slide rails and guide bars

- Weaving machines: longer intervals between maintenance operations due to minimum-quantity lubrication for gears, gripper looms and chains

- Finishing machines: resistance to water, steam, acidic and alkaline solutions for steamers, rolling bearings, compensators and rollers

- Stenter frames: less residue due to high separating effect on conveyor chains, adjustment spindles, needle bars and clips

OEMs recommendation: Monfongs, LK&LH, Pailung, Terrot, Mayer&Cie, Karl Mayer, Lonati, Santoni, Itema, Picanol, Rieter, Trutzschler, Savio, Stoll…

Vu Minh Company is the leading company in providing special lubrication products in textile industry. At the same time, with abundant warehouses, we are ready to meet the needs of customers in the shortest time.

| View more details on Kluber's Website |

|